Super Resin’s Integration Technology

We do not simply design and manufacture components; instead, we ascertain needs based on the entire system and identify problems in the mechanical and structural systems as a means of designing optimized specifications. By integrating various functions, we expand the range of new possibilities for CFRP products.

We understand the demands on the entire process, from system design to component manufacturing, assembly, verification, and evaluation, and are thus able to propose uniquely optimized solutions that go beyond meeting the customers’ specific requirements for composite parts and components, to meet their specific requirements for performance right from the conceptual stage.

System Integration Cases

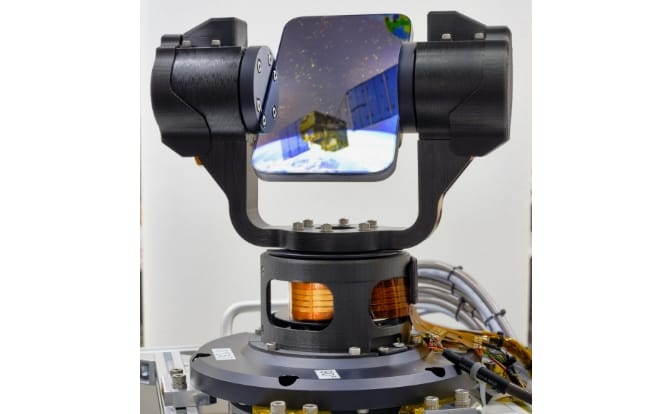

Two-axis Gimbal Mechanism, Optical System

(JAXA Project: Proof-of-Principle Model for Artificial Satellite-related Systems)

As part of JAXA’s GOSAT (Greenhouse gases Observing Satellite) project, we worked on a proof-of-principle model for a system on an artificial satellite designed to measure the earth’s carbon dioxide levels.

In this case, we designed and manufactured the mirror drive unit for the pointing mechanism. In addition, we successfully developed and in-housed the PI film copper plating and cutting processes for the FPC required to drive the motor in order to deliver a uniquely shaped FPC that matched the design.

| Research and Development Items |

|

|---|

Alignment Mechanism Component

(NEDO* Project: FY2018 Space Environment Reliability Verification Integrated System)

As a range of new businesses emerge on the back of artificial satellite data, higher precisions and lower costs are now required for the optical sensors, antennas, and other mission equipment. We developed a new alignment device that makes shape corrections in orbit in aims of achieving remarkable observation precision with small satellites.

*NEDO:New Energy and Industrial Technology Development Organization

https://www.nedo.go.jp/english/index.html

| Research and Development Items |

|

|---|